Material Handling Hose

Orientflex offers you different types of material handling hose. While all of them are made according to international standards.

Material Handling Hose

Material handling hoses are mainly to transfer the bulks. While the medium can be dry and wet materials such as sand, grit, grout, cement, grout, grain, seed, slurry and many others. As for the application, material hose widely serves in construction, building, sandblasting paint, mining, municipal, etc. To meet the requirements of these applications, material hose adopts high quality and abrasion resistant materials like NR, SBR, PU or others. While in order to work at the harsh conditions, bulk rubber hose usually has a wear and weather resistant cover. As for the connection style, it is various. While it can be camlock, connector, flange and many others. Then you can connect them to a various of equipment.

Orientflex offers you a series of material handling hoses to fit various usages. While our hose is ideal for ventilation, ducting, fume removal, dust collection and woodwork. As foe the material, we can offer you both rubber hose and thermoplastic hose. In a word, you can get the exact bulk material hose which fit you well.

Sand Blast Hose

Sand blasting hose is to spray abrasive materials such as sand, shot, gravel at a high pressure. While it’s to do the clean work on the metal surface.

Peristaltic Pump Hose

Peristaltic hose is specially designed for the peristaltic pump. It is reinforced with 4-8 layers of steel wire. While it can deliver abrasive materials and food.

Concrete Pump Hose

Concrete pump hose is to pump the abrasive materials such as cement, concrete, grout and many others. While such hose is highly abrasion resistant.

Concrete Hose 1230 PSI

Such concrete hose can bear higher pressure than the normal hose. While it can work at max 1230 Psi. It’s made from abrasion and weather resistant SBR and NR.

Slurry Hose

Slurry hose pipe is made from high qualiyu SBR or NR. Thus it has great resistance to abrasion, weather, cutting and aging. It’s mainly for the slurry transfer in mines.

Bulk Rubber Hose

Bulk hose is for suction, discharge and gravity flow of abrasive and bulk materials such as sand, gravel and cement in construction and factory.

Bulk Discharge Hose

The hose is made from synthetic rubber with high strength synthetic cord and anti static helix wire reinforce. Then the rubber hose is resistant to abrasion, weather and ozone.

Grout Hose

The hose is made from NR/SBR and reinforced with four or six plies of textile and a static wire Thus plaster hose is resistant to abrasion, weather and static.

Concrete Vibrator Hose

The hose is used for compressed air in electric and pneumatic vibrators with strong structure and good flexibility. It can work at -20℃-70℃.

Sweeper Hose

The is a suction hose for high abrasion granulates and powders. With exceptional flexibility, it’s also compressible and ideal for unaligend manifolds.

Layflat Cement Discharge Hose

Reinforced with 2 plies high tensile synthetic fabric and with cloth impression NR/SBR cover, the hose is highly resistant to abrasion and weather.

Gum Rubber Hose

Gum hose is designed for dry/wet abrasive material suction/discharge, industrial vacuum equipment and drill cutting suction hose in mobile drilling rigs.

How Orientflex Control The Quality Of Material Handling Hose

- Import the top grade raw material from Germany and Japan

- Introduce the advanced production equipment from Italy

- Supported by Korea and Italy technology

- Constantly improve the formula

- Set up complete quantiy control system

- Set up professional and reliable quality inspection team

- Own over 150 professional and advanced engineer

- Set up advanced lab with advanced testing machinery

- Support the third party test

Features Of Material Handling Hose

- High pressure resistant

- Corrosion and chemical resistant

- Weather and ozone resistant

- Extremely abrasion resistant

- Wide range of working temperature

- Smooth inner tube makes the medium flow effectively

- Long service life

- Any colors, sizes and prients can be customized

- Various types are available

- Ideal for all various applications such as mining, sandblasting and construction

Why Orientflex Is Your Unique Material Handling Hose Supplier

- Produce the material hose with top grade raw material

- Advanced production equipment bring you the best bulk material handling hose

- Various production standard meet all of your requirement

- One-stop service make you can get the relevant fittings

- Special OEM and ODM service make you can get the exact hose with special specs

- Strong supply capacity (90 containers/month)

- Professional technical and sales team offer you the best solution

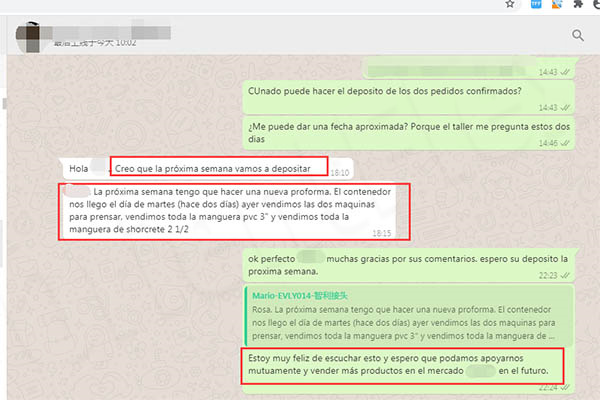

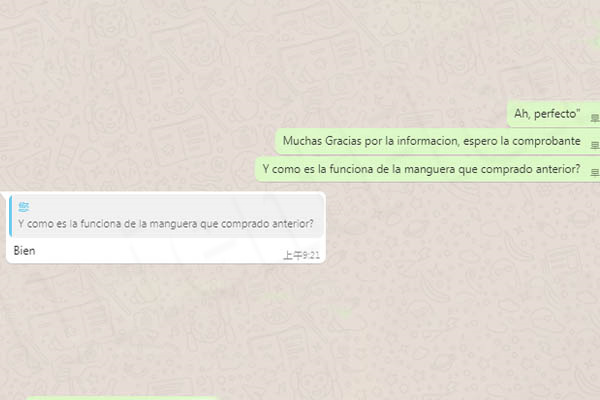

Good Reputations From Our Client

Bulk Material Handling Hose Loading And Delivery

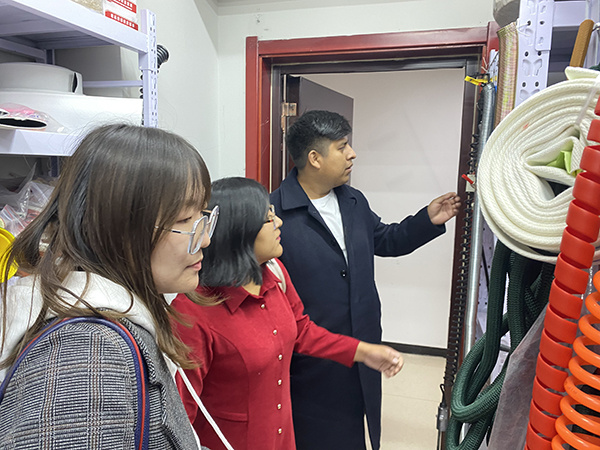

Client Visiting

Orientflex Exhibition Show

Leave Your Message

Please enter the information below and we will process your request immediately. If you have an urgent requirement, please call us at +86 17332912071 or Email:orienthose@orientrubber.com.