BOP Hose

BOP Hose

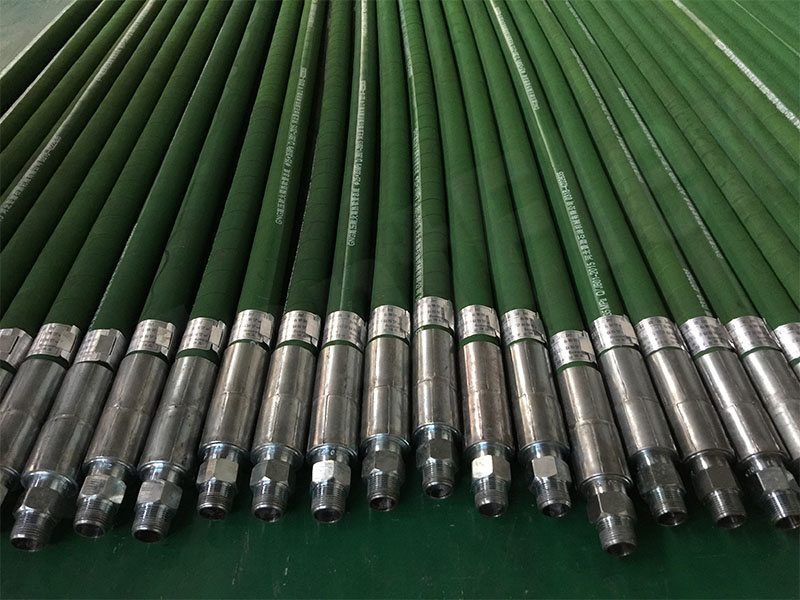

BOP hose is made from abrasion, corrosion and oil resistant modified nitrile rubber. Besides, it is a armed with a stainless steel cover. While this steel cover protect the rubber tube from cutting, corrosion and the effect by the weather.

BOP Hose

Tube: Black, abrasion, corrosion, oil and up to 20% H2S resistant modified nitrile

Reinforcement: Multiple layers of textile fabrics and steel cables, with one layer middle rubber placed among cable layers

Cover: Stainless steel armored rubber cover resists abrasion, corrosion, cutting, gouging, oil and weather

Temperature: -40℃ to +100℃ (-40℉ to +212℉)

Application: Blow out preventer (BOP) systems requiring high pressure, high temperature and flame resistant control lines

Armored hose assemblies with flame resistant cover withstand min 1300°F (+700°C) flame temperature at working pressure for 5 minutes without failure.

Bop Hose Features

Germany Lanxess HNBR as raw material

20% H2S and 80% oil based mud

Survive the extreme oilfield application requirements

Stainless steel 316L used as armored jacket

Bop Hose Couplings

Crimped couplings with over-ferrule fire protection.

Bop Hose Options

Accessories such as API 16D quick connector, self-sealing union and exterior armor are available upon request to protect hoses against extreme environmental damage.

Each hose is tested at 10000 psi for 15 minutes. Pressure test graph, test certificate and letter of conformance are issued for each hose.

5,000psi WP – 10,000 psi tested pressure-15,000 minimum burst pressure.

Bop Hose Specification

| ID | OD | WP | BR | Weight | L | ||||||

| inch | mm | inch | mm | Mpa | psi | inch | mm | kg/m | lb/ft | m | ft |

| 1/4 | 6 | 0.77 | 20 | 35 | 5000 | 4 | 102 | 0.66 | 0.37 | 100 | 330 |

| 3/8 | 10 | 0.93 | 24 | 35 | 5000 | 5 | 127 | 0.66 | 0.77 | 100 | 330 |

| 1/2 | 13 | 1.05 | 27 | 35 | 5000 | 7 | 178 | 0.98 | 0.63 | 100 | 330 |

| 3/4 | 19 | 1.38 | 35 | 35 | 5000 | 9.5 | 241 | 1.64 | 1.05 | 60 | 200 |

| 1 | 25 | 1.67 | 42 | 35 | 5000 | 12 | 305 | 2.62 | 1.77 | 60 | 200 |

| 1.1/4 | 32 | 2.11 | 54 | 35 | 5000 | 16.5 | 419 | 3.94 | 2.67 | 60 | 200 |

| 1.1/2 | 38 | 2.41 | 61 | 35 | 5000 | 20 | 508 | 4.59 | 3 | 60 | 200 |

| 2 | 51 | 2.96 | 75 | 35 | 5000 | 25 | 635 | 8.53 | 5.73 | 60 | 200 |

You May Also Like

Rotary Hose

Vibrator Hose

Cementing Hose

Leave Your Message

Please enter the information below and we will process your request immediately. If you have an urgent requirement, please call us at +86 17332912071 or Email:orienthose@orientrubber.com.