Structure

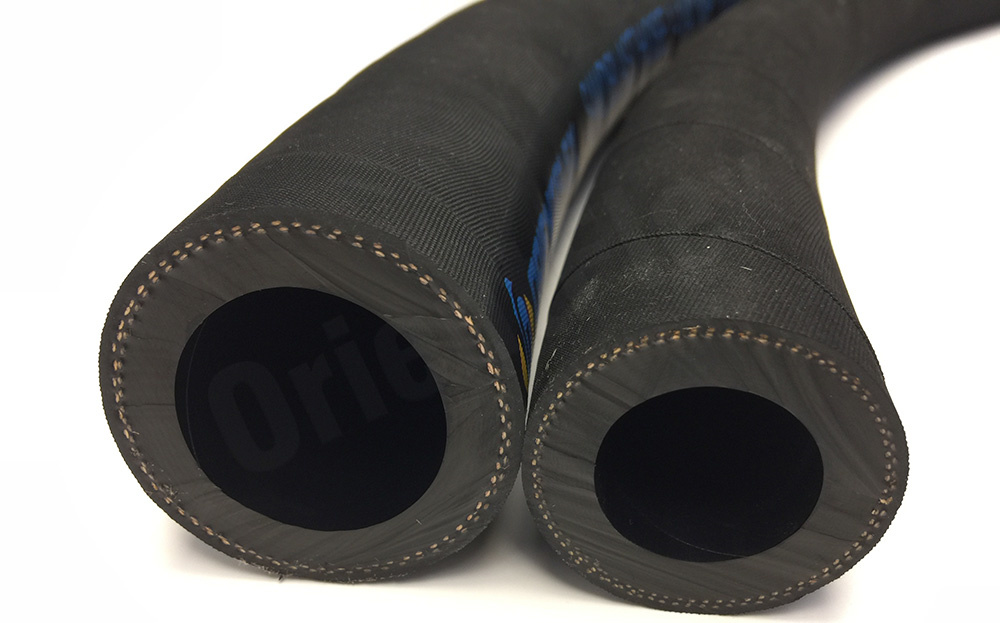

The rubber steel wire hose consists of inner layer, winding layer, steel wire layer and outer layer.

Classification

Water rubber hose: suitable for general water transfer and for use in environments from -20℃ to 45℃.

Air hoses: suitable for transporting compressed air and inert gases, for use in environments from -20℃ to 45℃.

Oil resistant hoses: suitable for transporting conventional oil, in environments from -20℃ to 45℃.

High temperature resistant hoses: suitable for transporting water up to 100℃.

Steam hose: suitable for conveying hot water or saturated steam below 170℃.

Acid and alkali resistant hoses: conveying dilute acids and alkalis with aconcentration of up to 40%, used in environments from -20℃ to 45℃.

Sandblasting hose: suitable for metal surfaces for sandblasting and sanding by air pressure.

Notes on use

As a rule, wire hoses should be used at the appropriate temperature and within the limits indicated. One of the main purposes of this is to better protect the hose.

In this process, we should consider the pressure and temperature conditions in a comprehensive manner.

We should have an understanding of the assembly situation. In the process of assembly, choose the right size of hose. In the process of installing the matching use, the shape of the hose, the appropriate treatment.

When fitting the corresponding couplings into the hoses, confirm the stability of the connections. The person in charge should check it regularly.

The temperature at which the hose is used, fluid flow rate and the pressure situation. We have to grasp and understand accordingly.

After use, store accordingly. Store in a relatively well-ventilated area, away from sunlight.

Of course, if you need any of these products you can find out more details from the Orientflex website. For more specific product information, please look out for the next article.