Food Grade Hose

Food hose is made from high quality food grade material. While it is produced according to strict standards. Orientflex offers you the complete series of food safe pipes. No matter you are woking on dairy, wine or beverage, you can find a reliable hose here.

Food Hose

Orientflex has worked on food grade hose producing and exporting over 17 years. And now, we are a leading supplier for food grade tubing and food safe hose. Since set up, we aims at supplying the most cost-effective hoses to the world. As for the food hose, we can offer you various types food grade flexible tubing including food grade PVC pipe, food grade rubber hose and food grade silicone tubing.

Food grade PVC tubing is highly flexible and wear resistant. Besides, food safe PVC pipe is more affordable than other hoses. While food grade rubber tubing has great air tightness. Besides, it is non toxic and odorless. Thus food grade rubber pipe will not pollute the medium. While silicone food hose performs much more better. Because i is a high temp food safe pipe which can bear over 200℃.

Food Grade Rubber Hose

Made from food grade nitrile rubber or EPDM, such rubebr food hose is designed to deliver foods such as milk, juice, beer, edible oil and so on.

Food Suction Hose

Food suction hose is made from high grade raw material. While it meets USDA and FDA standatds for food handling. It can bear the negative pressure.

UHMWPE Food Hose

UHP food hose is a special rubber food hose. Because it has a UHMWPE lining. While this makes the food safe hose chemical and corrosion resistant.

Wine Hose

PVC wine hose is specially designed for wine factory. It is to deliver the grain and other raw materials. The hose is made from food grade PVC material and it’s safe for wine.

PVC Washdown Hose

PVC washdown is made from high quality PVC material. While it is to do the clean work in food industry like dairy, juice factory and beer factory.

Washdown Hose

Washdown hose meets the food grade requirements. While it is to do the clean work in food industry, especially for dairy and beverage factory.

PVC Steel Wire Hose

PVC steel wire reinforced hose can be made into food grade. While it can transfer liquid foods like dairy, beer, juice and other kinds of beverage.

Silicone Braided Hose

Silicone braided hose is made from high quality silicone with a yarn braid. It is not only ideal for food use, but also ideal for medical use.

Silicone Vacuum Hose

Silicone vacuum hose is the great material for food and medical use. In our daily life, it serves as the coffe machine hose, baby nipple and many others.

Wire Reinforced Silicone Hose

Steel wire reinforced silicone hose has a spiral steel wire as the reinforce layer. Thus it has great pressure resistance. It is also ideal for medical and industrial use.

How Orientflex Control The Quality Of Food Transfer Hose

- Import the top grade raw material from Germany and Japan

- Introduce the advanced production equipment from Italy

- Supported by Korea and Italy technology

- Constantly improve the formula

- Set up complete quantiy control system

- Set up professional and reliable quality inspection team

- Train over 150 professional and advanced engineer

- Set up advanced lab with advanced testing machinery

- Support the third party test

Features Of Food Transfer Hose

- Nontoxic and odorless

- Good air tightness

- Will not pollute the medium

- Special UHMWPE lining

- Weather and ozone resistant

- Abrasion resistant and durable

- Any colors, sizes and prients can be customized

- Various types are available

- Ideal for all the processes in food industry

Why Orientflex Is Your Unique Food Hose Supplier

- Produce the food hose pipe with top grade raw material

- Advanced production equipment bring you the best food hose

- Various production standard meet all of your requirement

- Different types of food hose cover all the food industries

- One-stop service make you can get the food grade hoses and fittings

- Special OEM and ODM service make you can get the exact food safe pipe that you want

- Strong supply capacity (90 containers/month)

- Professional technical and sales team offer you the best solution

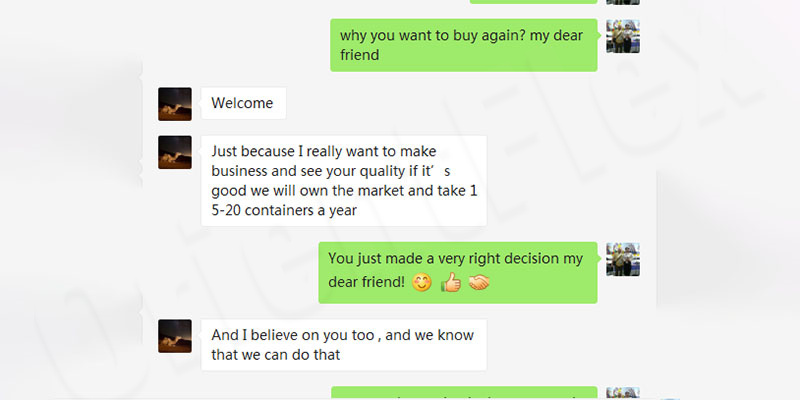

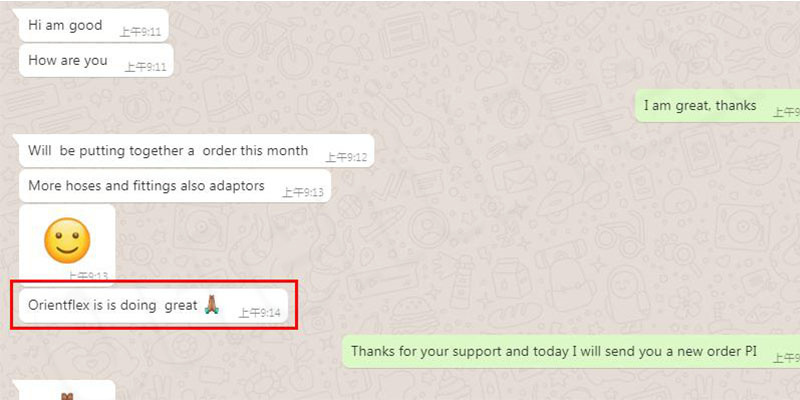

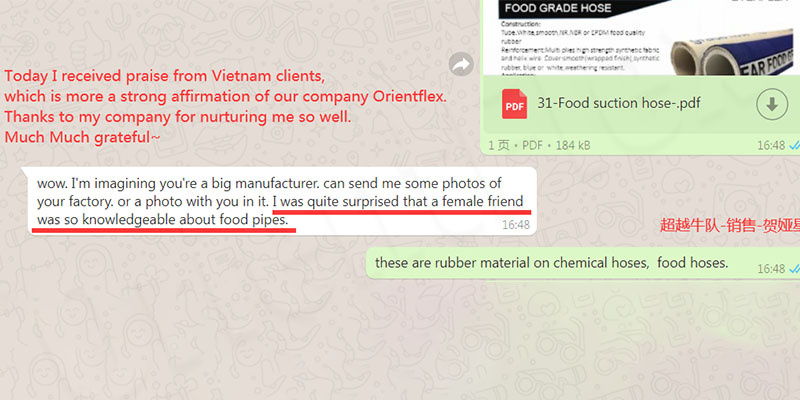

Good Reputations From Our Client

Food Hose Loading And Delivery

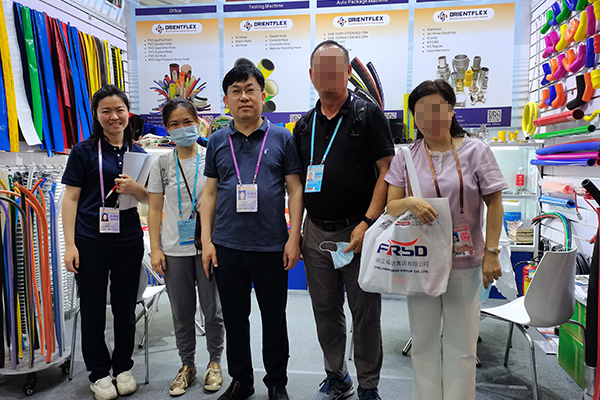

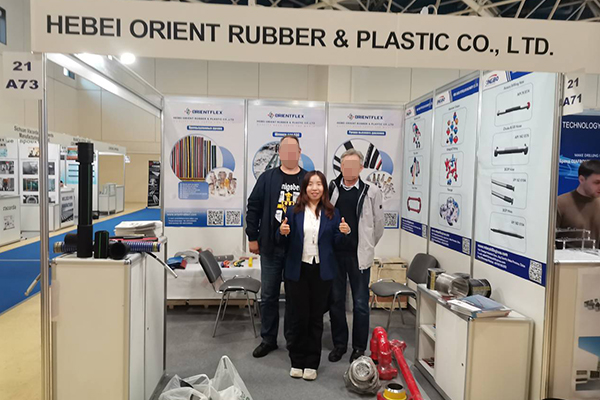

Orientflex Exhibition Show