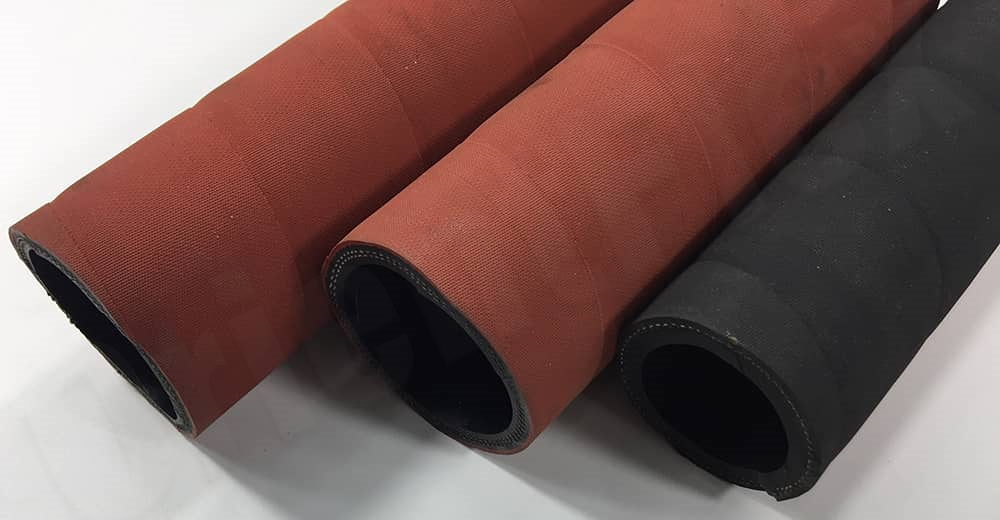

Rubber hose is a common material in any industries. It’s to deliver various materials like air, water, oil, etc. In the daily use, there will be several problems on the hose like leakage and burst. Then how to maintain the rubber tube to avoid such problems?

The first step is to check your rubber hose regularly

During the use of rubber pipes, due to the temp, moisture and air, they will age. In addition, the rubber hose joint will also wear to a certain extent. Therefore, you should inspect your rubber hose regularly, usually once a week. So that you can find these problems and replace a new hose in time.

Then take some anti-friction measures on the rubber tube

You may drag the rubber hoses around a surface during use. For example, pressure washer hose. Although rubber tube is wear proof, this does not mean that you can avoid the damage caused by friction. Here, we Orientflex recommends you spiral protective sleeve. Our spiral guard adopts modified PP material. While it perfectly combines the elasticity of PP with the friction resistance of PE. Thus it performs very well in protecting your flexible rubber hose. After testing, under a pressure of 1.9MPa, the wear thickness was only half a millimeter after continuous grinding for one thousand kilometers. Therefore, after using the spiral protective sleeve, you no longer have to worry about the friction. Besides, it can extend the service life of the rubber tube for at least three years.

The second is the cleaning the rubber hose before and after use

During the use, some dust, oil and other pollutants may adhere to the rubber hose. If this happens for a long time, it will cause corrosion and other damage to the outer rubber layer. Thus you should do some cleaning work on the hose regularly. After the cleaning, keep the inside and outside of the hose dry. Then store it in a dry and dark place.