The wind power industry refers to a series of industrial chains that utilize wind energy to generate electricity. Looking deeper, the wind power industry is actually the product of multiple factors such as technology, energy and economy. It is related to national energy security and sustainable development of the ecological environment. It is more about the overall situation of global response to climate change. With the global emphasis on renewable energy, the wind power industry has ushered in a period of rapid development. In this process, silicone hose, as an important supporting product, are widely used in the wind power industry.

Specific applications of silicone tube in the wind power industry:

Hydraulic system

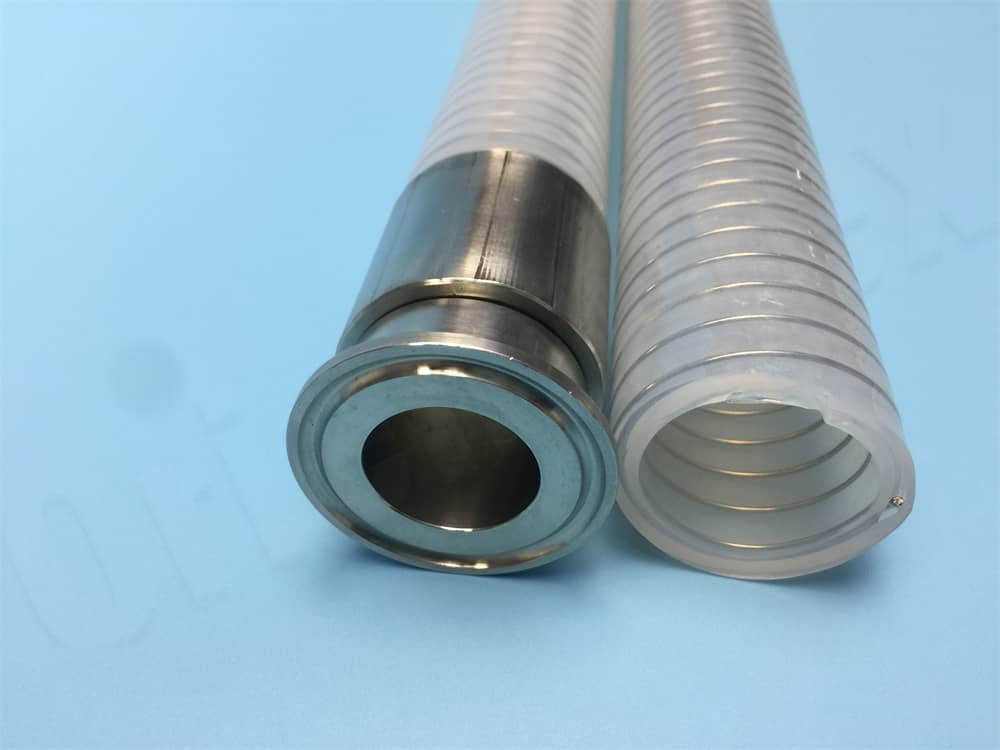

Silicone tubes are widely used for pipe connections in wind hydraulic systems. Because silicone hose has good high temp, corrosion and pressure resistance. Therefore, it can work stably in high temp and high pressure environment. Therefore, the use of silicone pipe in wind hydraulic systems can ensure the reliability and safety of the system.

Cooling system

In wind turbines, silicone tubes are used as piping connections for cooling systems. Wind turbines require cooling systems to dissipate heat to maintain operational stability and efficiency. Silicone tubes are used for their excellent thermal conductivity and high temperature resistance. This results in efficient heat transfer and ensures efficient system operation.

Thermal protection

Silicone tube is also ideal for thermal protection in wind turbines. Wind turbines are affected by the external ambient temperature during operation. Silicone tubes can provide good thermal insulation effects. It protects critical components from temperature fluctuations. This ensures the normal operation of the wind turbine.

Cable protection

A large number of cable runs are required in wind turbines. Silicone tubes can be used to protect cables. Silicone tube has excellent insulation properties and voltage resistance. Therefore, it can effectively isolate the cable from the external environment. Then prevent moisture, corrosion and other factors from damaging the cable.