Acid resistant hose has many types. While it can be hydraulic hose, food hose, slurry hose, sand blast hose, oxygen acetylene hose, etc. These rubber tubes are acid and alkali resistant. As for the material, it can be natural rubber, NBR, SBR, EPDM, etc. Each of them has its own advantages. Then let me show you next.

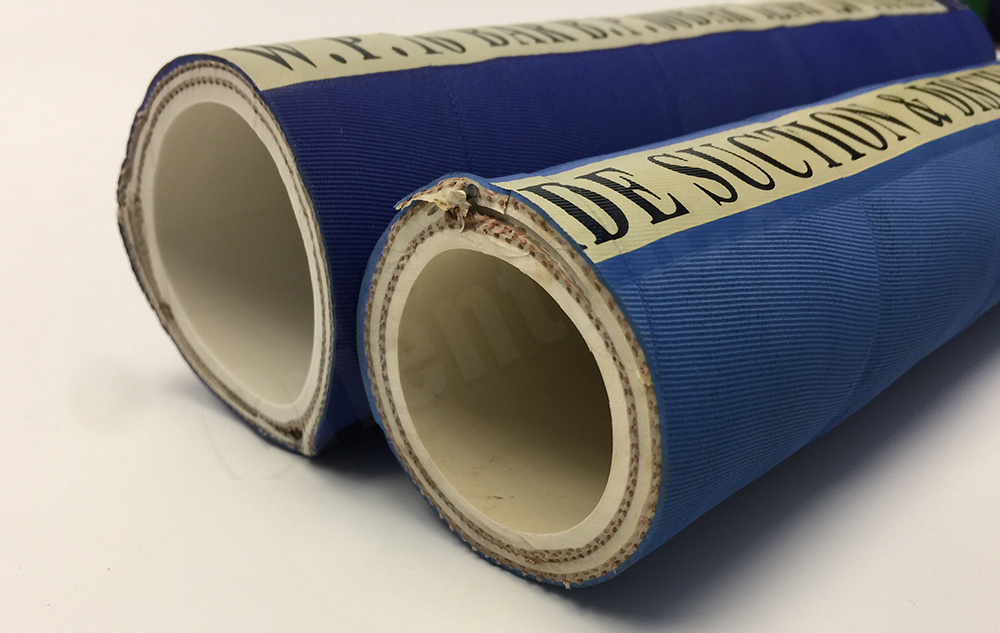

EPDM acid resistant hose

If you requires for acid and alkali resistance, EPDM is better. Because it performs very well in acid resistance. Besides, it has excellent temp and aging resistance. EPDM rubber hose can deliver 35% concentration of acid. The most common material of steam hose is EPDM. It is to blow the pipeline with high temp steam. While this is to avoid the hose get frozen in cold weather.

NBR rubber hose

Nitrile rubber has the best oil resistance among ordinary rubbers. It is more resistant to petroleum based oils than natural rubber, SBR and other non-polar rubbers.

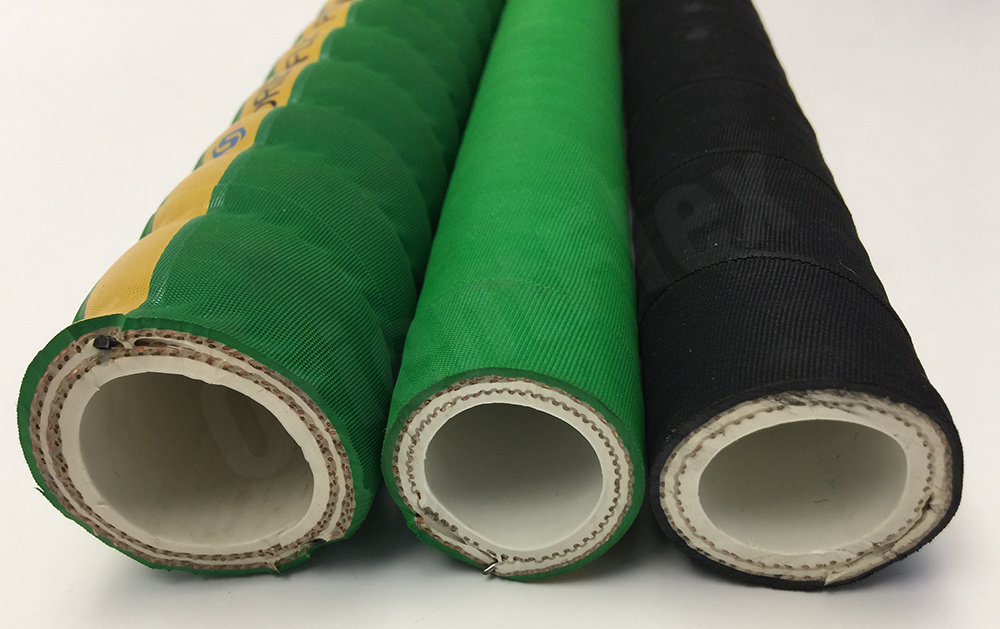

Material with high wear resistance

In general, sand blasting hose or jetting hose will use such rubber. Because the mediums of these hoses are sand, grit and other abrasive solids. Thus the hose must be wear proof. Otherwise it will break down during the work.

From above we can see there are many types of acid resistant hose. Thus when you choose such hose, confirm your work condition first. Then choose the most suitable one.