In the last piece, we learned some tips to protect the operator in sandblast work. While this time let me introduce you other steps.

Operator Position

Maintain a safe distance from the sandblast nozzle to avoid direct contact with the abrasive stream. Position yourself in a way that min exposure to rebound abrasive particles.

Anti-static

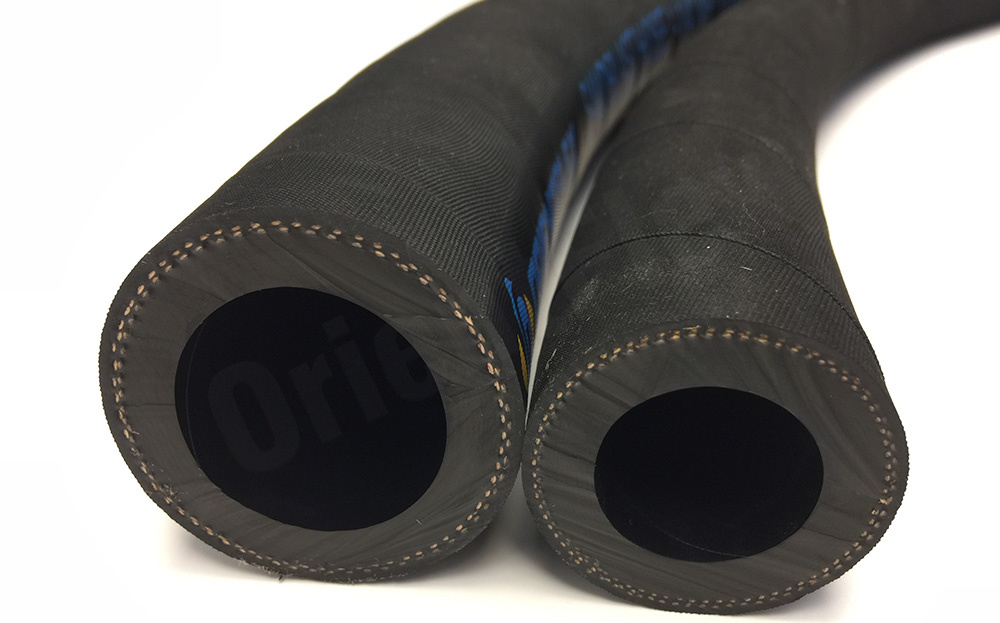

If there is a risk of static, you have to take some measures to eliminate it. Thus you should ensure that the hose has a copper wire to dissipate static. Then this helps prevent sparks.

Train

Sandblast work requires skill. Thus ensure that operators are trained to safely do the blast work. Then there will be less safety risk.

Work Condition

Be mindful of the work condition when do the blast work. While you have to prevent the abrasives into sensitive areas. For example, water source or nearby vegetation. Then take measures to collect the dust in a container.

Emergency Prepare

Have a clear sense of emergency procedure and be prepared to respond to any accident. This includes knowing how to shut off the blast switch, access emergency exits and provide first aid if needed.

Sand blast work is very dangerous and have high risk to cause serious problem. Thus you should take safety measures to keep safe. Then you can refer to the above tips for safety. Besides, you can consult the sandblast hose supplier for some tips.