Let’s think about it, what are the pressure hoses used for. Sometimes, we required pressure hoses to do the cleaning job, such as cleaning tubes, removing paint and dirt, etc. They made of different materials with different strengths of reinforcement for being appropriate for different working scenarios. There are specialized tank cleaning hose, sewer flushing hose, sewer jetting hose, sewer cleaning hose, waterblast hose, pressure washer hose, 3/8 inch pressure washer hose, etc. Layman might consider these hoses are similar. However indeed, each type of hose is made of different material, size, adopted different reinforcement technology, to make it exactly suitable for the project’s requirements. Besides the industrial cleaning job, an ultra high pressure hose is expected to do waterjet cutting. Please, do not underestimate the effects of high-presure water. In addition, ultra high pressure hoses can be applied in the hydraulics for hydraulic tensioners, testing devices, etc.

Waterjet cutting technology is widely used in abrasive jet cutting for industrial applications. Waterjet cutting is able to precisely cut complicated shapes without damaging the material’s surface by a high temperature or compromising the material’s inner structure. To achieve the waterjet cutting, the ultra high pressure hose should be matched for the appropriate pressure of the precision waterjet cutting machine requires. By the way, the assembly nozzle should be more narrow for precise cutting. There is high compatibility of multi-spiral thermoplastic hoses with fittings and ferrules of Orientflex produced. Orientflex has four series of ultra high pressure hose, which can satisfy your requires.

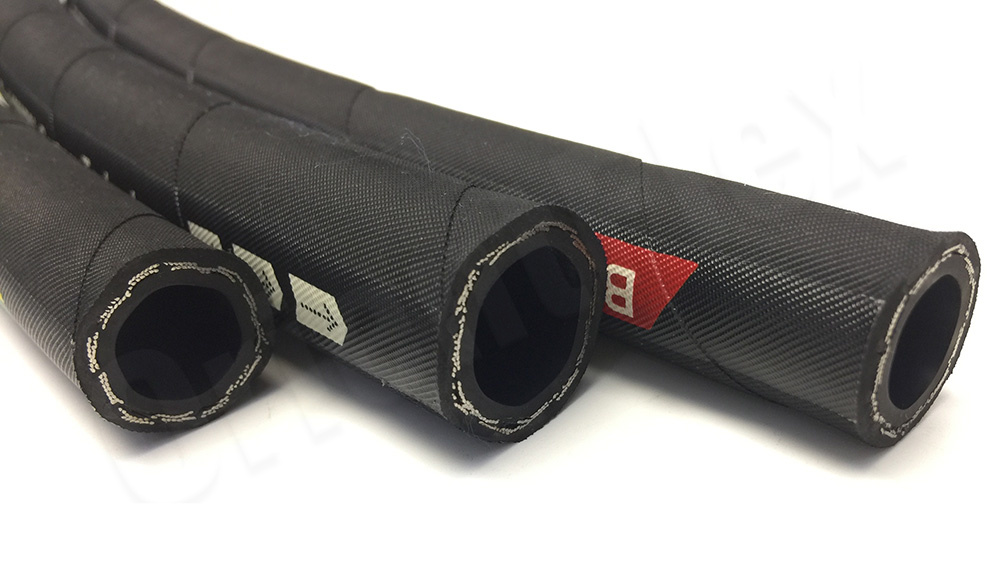

Ultra high pressure hose SSB201 and SSB401, these two series’ inner tube is made of polyamide (PA), and out cover is pin picked anti-abrasion polyurethane. SSB201 is reinforced by two spiral layers and one layer high tensile steel wire braiding. SSB201 has 1/4″, 5/16″, 3/8″, and 1/2″ size, which can withstand 110 MPa, 100 MPa, 80 MPa, and 70 MPa accordingly. SSB401 is reinforced by four spiral layers and two layers of high tensile steel wire braiding, thus can withstand higher working pressure (about 50 MPa more than SSB201). Ultra high pressure hose SS200 and SS400 adopt polyoxymenthylene inner tube, and out cover is polyamide. SS200 is reinforced by two spiral layers of high tensile steel wire. Sizes are from 1/8″ to 5/16″. SS200 can take around 100 MPa working pressure. SS400 is reinforced by four spiral layers of high tensile steel wire, which allows higher working pressure.

If your project requires ultra high pressure hoses for waterjet cutting, industrial cleaning or hydraulics, you can tell Orientflex your using purpose, you will get the best quality and the most suitable hoses for your project.